Precision in Plastic Injection Molding with a Commitment to Quality and Innovation.

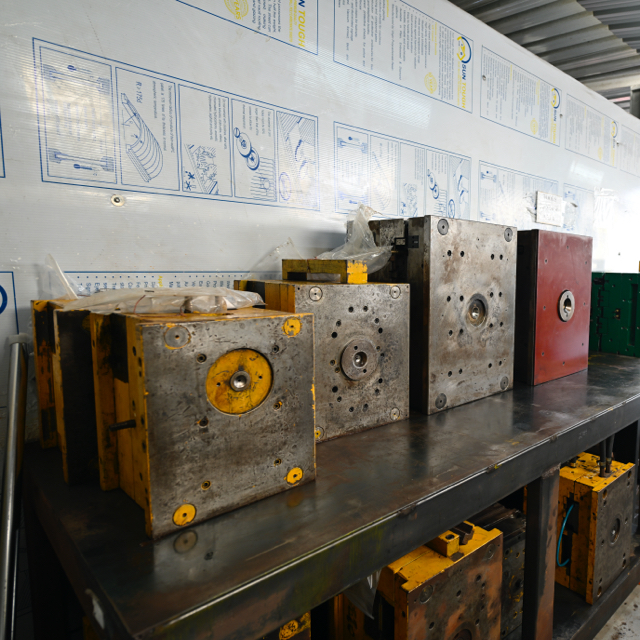

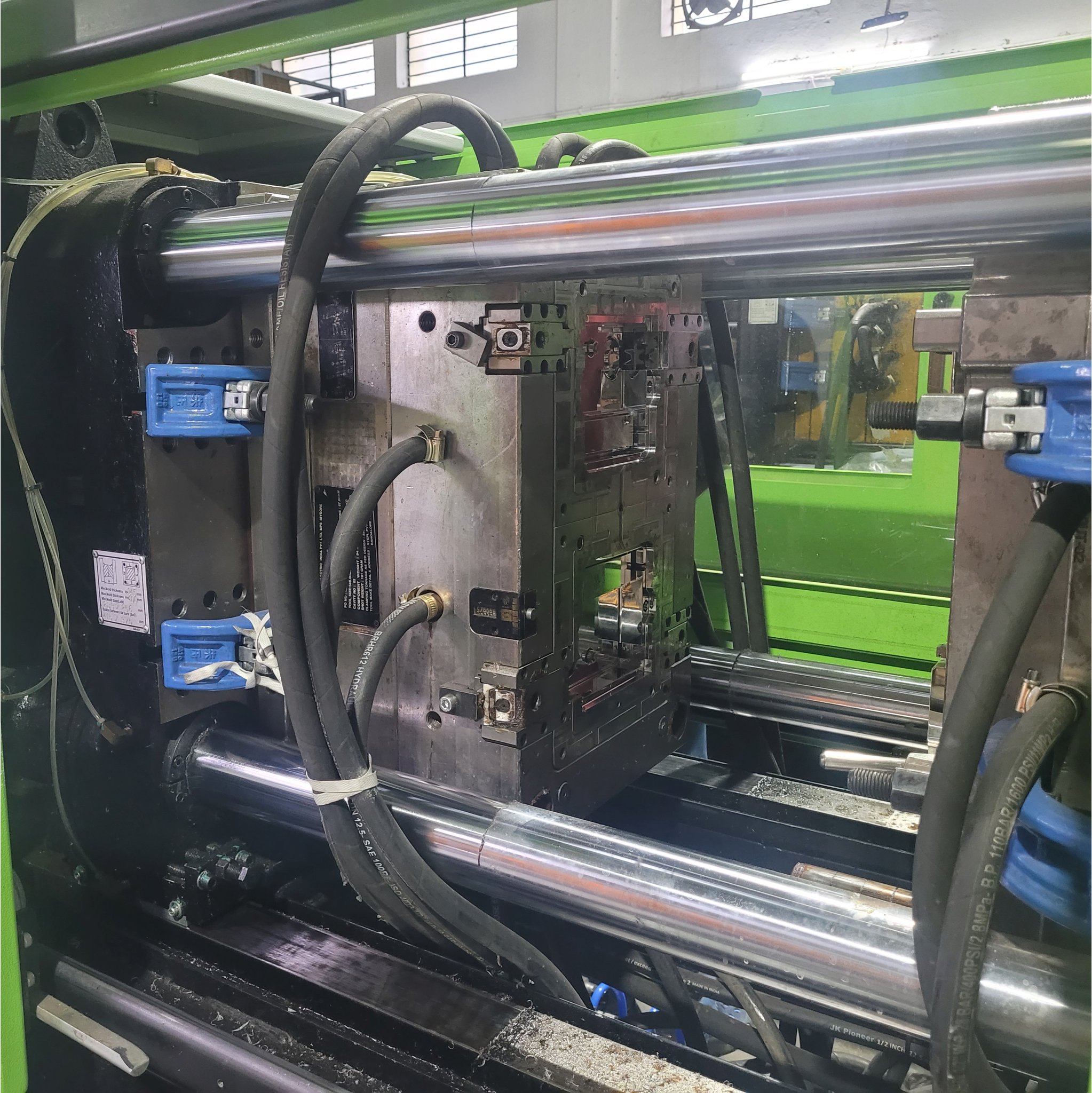

V4 Tech Private Limited is a Mysuru-based plastic injection molding component manufacturer specializing in high-precision engineering plastic components for electrical, auto electrical, automotive, medical, and engineering industries. We process specialized components using advanced engineering plastics that ensure durability, consistency, and superior performance.

Guided by a strong quality culture and ISO-certified processes, we combine modern injection molding technology with skilled expertise to deliver reliable and cost-effective solutions. Our vision is to serve global MNCs with world-class products, while our mission focuses on sustainable growth through employee development and continuous innovation.

At V4 Tech, we believe that engineering precision and customer satisfaction drive success — shaping a future where quality and trust define every molded component we create.